ROTAMETER

What are Rotameters ?

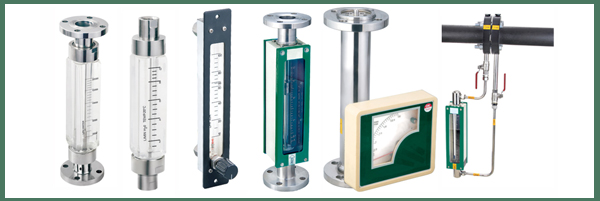

The rotameter is an industrial flowmeter used to measure the flowrate of liquids

and gases. The rotameter consists of a tube and float. The float response to

flowrate changes is linear, and a 10-to-1 flow range or turndown is standard. In the

case of Flowtel Engineering, far greater flexibility is possible through the use of

correlation equations. The rotameter is popular because it has a linear scale, a

relatively long measurement range, and low pressure drop. It is simple to install

and maintain.

What are Rotameters ?

The rotameter is an industrial flowmeter used to measure the flowrate of liquids

and gases. The rotameter consists of a tube and float. The float response to

flowrate changes is linear, and a 10-to-1 flow range or turndown is standard. In the

case of Flowtel Engineering, far greater flexibility is possible through the use of

correlation equations. The rotameter is popular because it has a linear scale, a

relatively long measurement range, and low pressure drop. It is simple to install

and maintain.

Acrylic tubes are also used in some rotameter designs due

to their lower cost and high impact strength. They are

typically constructed of acrylic, with either metal or plastic

end fittings. With plastic end fittings, care must be taken in

installation,

Acrylic tubes are also used in some rotameter designs due

to their lower cost and high impact strength. They are

typically constructed of acrylic, with either metal or plastic

end fittings. With plastic end fittings, care must be taken in

installation,  For higher pressures and temperatures beyond the practical range of glass tubes, metal

tubes are used. These are

usually manufactured in stainless steel. The position of the

float is determined by magnetic or mechanical followers that can be read from the

outside of the metal metering tube.

For higher pressures and temperatures beyond the practical range of glass tubes, metal

tubes are used. These are

usually manufactured in stainless steel. The position of the

float is determined by magnetic or mechanical followers that can be read from the

outside of the metal metering tube.  The glass tube rotameter is precision formed of borosilicate glass, and the float is precisely machined from metal, or plastic. The

metal float is usually made of stainless steel to provide corrosion resistance. The float has a sharp metering edge/maximum

diameter where the reading is obser ved by means of a scale mounted

The glass tube rotameter is precision formed of borosilicate glass, and the float is precisely machined from metal, or plastic. The

metal float is usually made of stainless steel to provide corrosion resistance. The float has a sharp metering edge/maximum

diameter where the reading is obser ved by means of a scale mounted  When fluid or gas flows through a taper tube containing a float, a pressure difference of

P1 and P2 is created between upper and lower side of the float. The float moves upwards by a force

obtained by multiplying the pressure differential by the maximum cross sectional area of the float.

When fluid or gas flows through a taper tube containing a float, a pressure difference of

P1 and P2 is created between upper and lower side of the float. The float moves upwards by a force

obtained by multiplying the pressure differential by the maximum cross sectional area of the float.  A removable mechanism type Woltman Water meter /multijet

dry With magnetic drive and vacuum sealed register.

A removable mechanism type Woltman Water meter /multijet

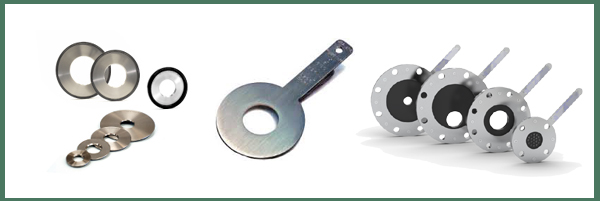

dry With magnetic drive and vacuum sealed register.  The bore and bevel is the standard method of limiting the plate edge thickness. The bevel is

machined at a 45° angle to the desired edge thickness. Unless otherwise specified, plates will be

bevelled to 1/50 of the line I.D. or 1/8 of the orifice bore, minimum governing.

The bore and bevel is the standard method of limiting the plate edge thickness. The bevel is

machined at a 45° angle to the desired edge thickness. Unless otherwise specified, plates will be

bevelled to 1/50 of the line I.D. or 1/8 of the orifice bore, minimum governing.  Flowtel series FLTF100 2 wire /FLTF200 4 wire turbine flow transmitter

specially used for various industrial applications. The flowing media engages

a vaned rotor causing it to rotate at an angular velocity proportional to flow

rate.

Flowtel series FLTF100 2 wire /FLTF200 4 wire turbine flow transmitter

specially used for various industrial applications. The flowing media engages

a vaned rotor causing it to rotate at an angular velocity proportional to flow

rate.