The Magnetic Level Gauge is the instrument to read a level indication inwhatever plant or operating conditions giving free maintenance, preventive security against leakage, environmental safety, sure and trouble freeapplication with chemically aggressive, pollutant, harmful or poisonous,inflammable or explosive, optically similar fluid interface.

- The principle whereby the liquid in communicating vessels is always at

the same level - Archimede’s principle according to which a body immersed in a liquid

receives a buoyancy equal to the weight of displaced liquid - The principle of attraction between North and South poles of two

permanent magnets and that of repulsion between like poles.

This principle has two applications in the magnetic level gauge - First between the magnet in the chamber float and every single

magnet of the indicating scale - second between the magnets of the indicating scale

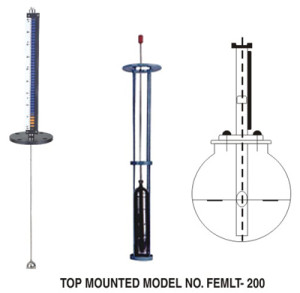

The magnetic level gauge consists of:

- A vertical chamber consisting of a tube of suitable diameter and thickness containing a float wherein a permanent

magnet is placed exactly on the liquid level line - Two horizontal stub pipes for connection to the vessel containing the liquid of which we wish to know the level

- Two stop valves (recommended, but not mandatory) one on each stub pipe, to isolate the level gauge

- An indicating scale, outside the vertical chamber, consisting of a case of non-magnetic material with transparent front

face containing a set of small permanent magnets enclosed in small cylinders which can rotate on their horizontal axis.

These cylinders show an external surface having two different colours.

According to the orientation of each magnet (due to the action of the magnet in the float) each cylinder will show externallyhalf of its surface of one colour or the other. The indicating scale will be of one colour (e.g. white) over the chamber area taken up by gas, vapour or steam phase contrasting with the other colour (e.g. red) over the chamber area taken up by liquid phase.

The application range is very wide and includes all the situations where the fluids are:

- At high pressure, at low or high temperature

- At low pressure, at low or high temperature

- Chemically aggressive

- Pollutant to environment

- Noxious or poisonous for people health

- Inflammable or explosive

- With identical optical characteristics of the superimpose phases

(interface)

| (1) Height of the tank & height of the nozzle welded on it |

|---|

| (2) Name of the liquid |

| (3) Material of construction of wetted parts |

| (4) Specific gravity of the liquid |

| (5) Operating temperature |

| (6) Operating pressure |

| (7) Top nozzle detail on which you are intending to mount level indicator |